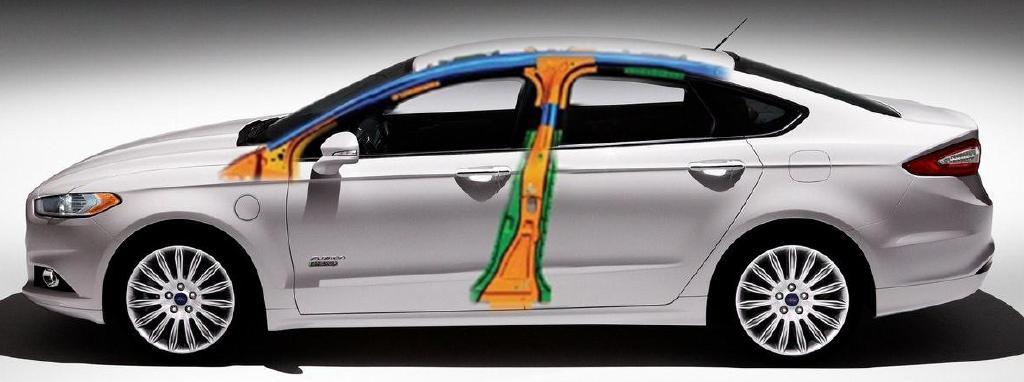

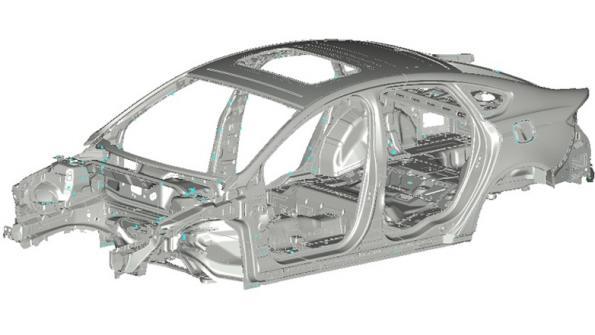

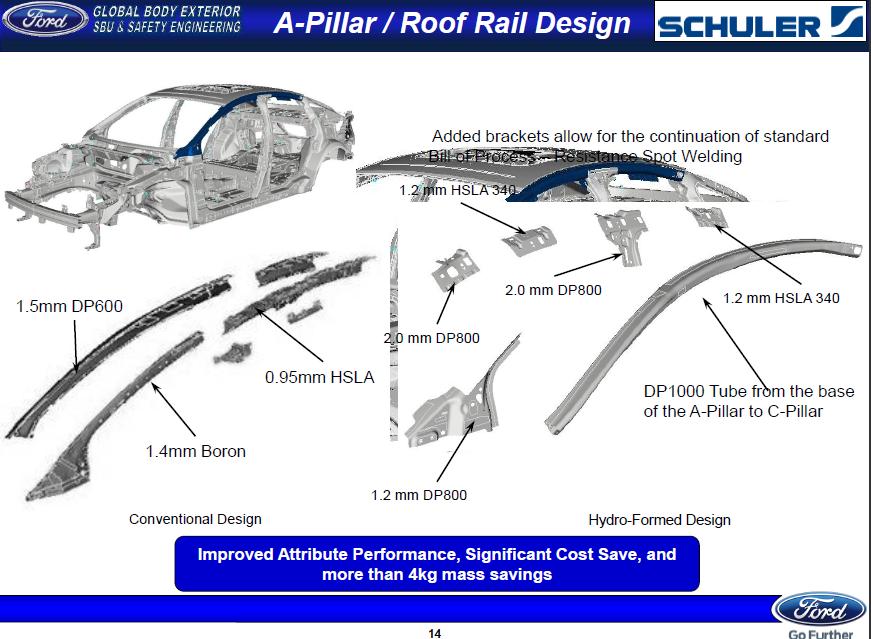

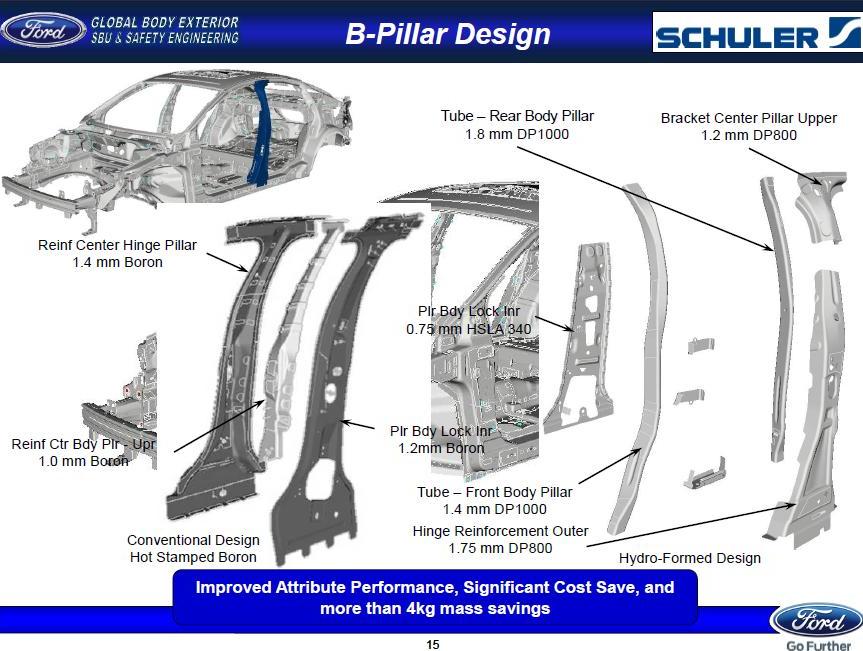

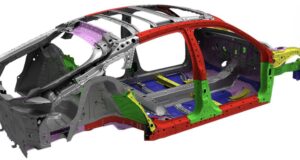

The 2013 Ford Fusion uses hydroformed steel tubes for its B-pillars and a hydroformed A-pillar roof rail. So why is this important to us? Using hydroforming instead of hot-stamped welded sheet to create the car’s roof-pillar structure reduced mass, saved cost, reduced the bill of material (which is the number of parts welded together to make the B-pillar), and helped improve the new Fusion’s crash performance. The hydroformed steel tubes replaced hot-stamped parts. B-pillars are a common place to find hot-stamped boron and the hydroformed steel tubes are replacing it in the 2013 Fusion.

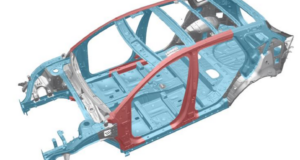

Take a close look at the two images below of the body structure of the previous design and the new hydroformed design. Notice that the previous design used boron steel and the new hydroformed design does not. I’m going to try to work some magic and see if I can get my hands on a 2013 Fusion but since it is new it might take a little time before showing up in scrap yards.

Boron Extrication An in-depth look into vehicle extrication and rescues involving today's automobiles

Boron Extrication An in-depth look into vehicle extrication and rescues involving today's automobiles