Remember all the boron and UHSS used in the 2009 F-150? Laser welding is used to mate the roof and body-side panels to the truck’s new roof structure. The roof structure is made from DP-780 super high-strength. The high-strength steel tubes run from the base of the A-pillar up through the roof, forming what is essentially a safety cage around the vehicle’s occupants. The structure also features the first use of Boron steel in the B-Pillar. So a good bet is the 2011 Ford Super Duty is going to have the same stuff, maybe even more!

Notice the front structure with the fender sheet metal removed in the image below? Looks just like the dual-phase steel used in the ultra-strong hydroformed front structure in the 2009 F150! These dual hydroformed front tubes are located on either side of the engine bay are shaped to absorb impacts.

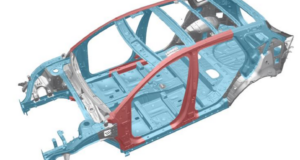

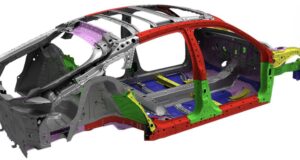

2009 F150 Body Structure

2009 F150 Body Structure Boron Extrication An in-depth look into vehicle extrication and rescues involving today's automobiles

Boron Extrication An in-depth look into vehicle extrication and rescues involving today's automobiles