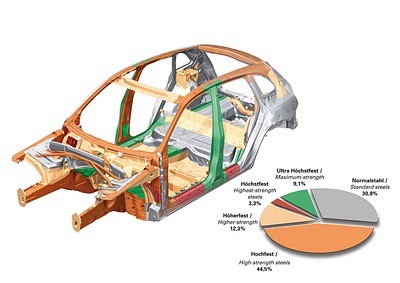

Body structure

The basic weight of the Audi Q5 at market launch is 1,730 kilograms (3836.04 lb), a low figure for an SUV of this size. The steel body is very light in weight, thanks to the intensive use of cutting-edge technologies.

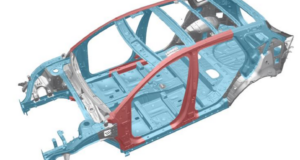

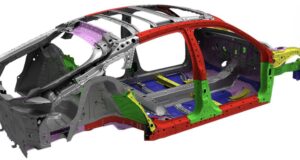

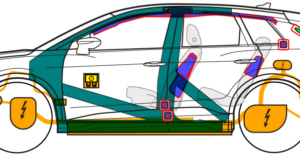

The super-strength steels that reinforce the center tunnel, inner sills, B-posts, longitudinal members and bulkhead cross-member in the luggage compartment have tensile strengths as high as 1,600 megapascals.

Six Audi Q5 cars together weighing ten metric tons could be hung from a strip of this hot-formed material only two millimeters (0.08 in) thick and 30 millimeters (1.18 in) wide.

Hot forming is a hi-tech process. It involves heating blanks of boron steel to 950 degrees Celsius (1,742° F) in a conveyor oven and then quenching and shaping them in a cooled die.

Their various zones can be heated to different temperatures in the oven, to produce a range of strength zones. In the event of a crash, the component is then deformed in precisely the desired manner.

In the case of the B-post, for instance, the lower zone is rather more ductile (deformable) than the upper zone, since this is where most energy has to be dissipated in the event of a side-on collision.

On the body of the Audi Q5 – minus the doors, lids and metal panels – superstrength hi-tech steels make up an impressive 9.1 percent of the overall weight. 3.3 percent is made from ultra-high-strength steels, 12.3 percent from higherstrength grades, 44.5 percent from high-strength steel and 30.8 percent from conventional deep-drawn steel.

Boron Extrication An in-depth look into vehicle extrication and rescues involving today's automobiles

Boron Extrication An in-depth look into vehicle extrication and rescues involving today's automobiles