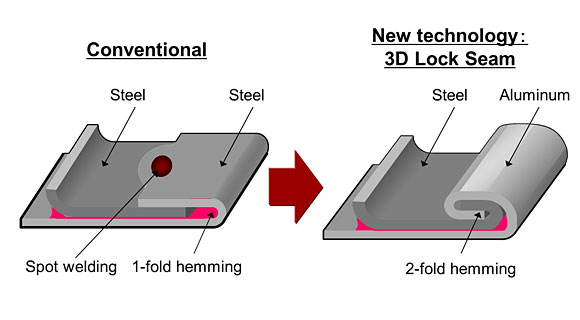

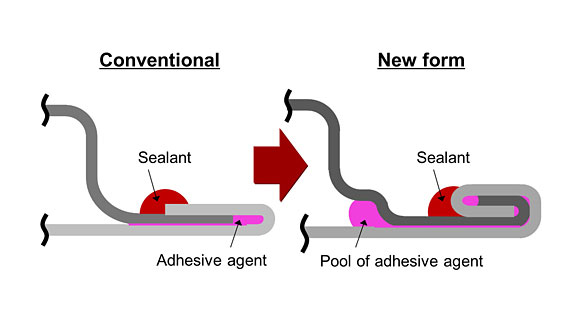

The new technology to join steel and aluminum that Honda uses will not very much for use in the extrication world except for one thing. If you look at the bottom 2 pictures you will see that this new technology adds an additional hemming on the flange. This should help keep the door outer sheet metal from separating from the inner door.

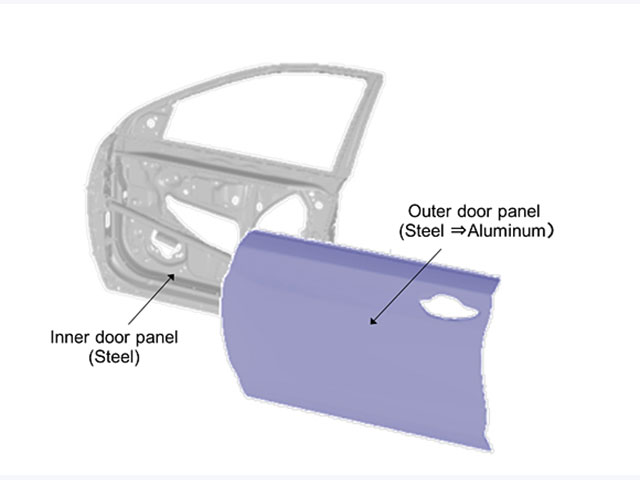

Honda developed a new technology to join steel and aluminum that enables the adoption of aluminum for outer car body panels. The first production application is the new 2014 Acura RLX. The technology allows to replace outer body panels which are conventionally made of steel with lighter ones made out of aluminum.

Honda used this application on the outer door panel of the 2014 Acura RLX that went on sale in the United States March 2013. The technology is expected to be adopted sequentially to other models.

To join together the dissimilar metals of steel and aluminum, the simultaneous establishment of several different technologies was required such as technologies to prevent corrosion (electrical corrosion) and thermal deformation caused by the different expansion rates of steel and aluminum. The advantages of these new technologies include elimination of a spot welding process required to join conventional steel door panels. The new technology contributes to the improvement of fuel economy and dynamic performance of the vehicle by reducing door panel weight by approximately 17% compared to the conventional all-steel door panel.

Boron Extrication An in-depth look into vehicle extrication and rescues involving today's automobiles

Boron Extrication An in-depth look into vehicle extrication and rescues involving today's automobiles