Steel ID in Modern Vehicles

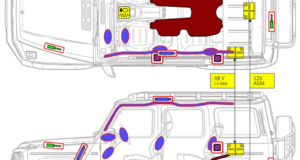

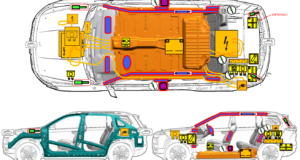

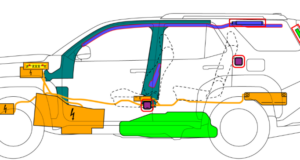

The A-pillar and roof rail reinforcement use dual phase steel. The 2010-11 Chevrolet Equinox and GMC Terrain utilize UHSS and dual phase steel. Here is an explanation of these steels and others:

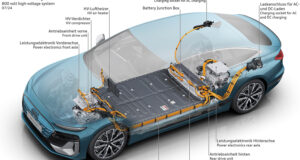

High strength steel (HSS). High strength steel is much stronger than low carbon steel or mild steel because of heat treatment. It has yield strength of up to 60,000 psi and experiences an increase in stress, exceeding this yield strength, when deformed during a collision. Some of the same properties that give HSS its strength can also pose some unique challenges. When high strength steel is deformed on impact, it’s more difficult to restore than mild steel.

Ultra high strength steel (UHSS). Ultra high strength steel is even stronger than HSS and is able to withstand stresses of up to 110,000 psi. When UHSS is damaged or bent, the usual recommendation is that it be replaced.

Boron steel. Boron steel is considered the “most ultra” of the ultra high strength steels. It has extremely high strength, with a yield strength of 196,000 to 203,000 psi. It can’t be straightened because of the extremely high heat used in manufacturing it. If straightening is attempted, it will more than likely crack. The only solution is to replace the part if damaged. Boron steel, on the other hand, is relatively easy to weld.

Dual phase steel (DPS). Dual phase steel is a high strength steel with properties that can be “tuned” for different strength levels and processing methods. DPS is less expensive to manufacture than other advanced high strength steels. Also, it’s easier to fabricate, especially in regard to welding, has excellent shock absorbing characteristics, and a yield strength of up to 116,000 psi.

Mild steel (MS). Also known as low-carbon steel, mild steel has a low level of carbon and is relatively soft, making it easy to repair. It can be safely welded or heat shrunk and cold worked without seriously affecting its strength. It has yield strength of up to 30,000 psi.

Hot-rolled steel. Hot-rolled steel is manufactured by rolling it at temperatures exceeding 1,472° F. It usually has a standard manufacturing thickness range of 1/16- to 5/16-inch (1.6 to 7.9 mm) and is primarily used for parts such as frames and cross members. This type of steel is quite rigid but relatively thick and heavy.

Cold-rolled sheet metal. Cold-rolled sheet metal is hot-rolled sheet metal that has been acid rinsed, cold rolled thin and annealed (reheated and then cooled in a controlled environment to strengthen the metal and prevent it from becoming brittle). It has a dependable thickness accuracy, surface quality and better workability than hot-rolled steel.

Boron Extrication An in-depth look into vehicle extrication and rescues involving today's automobiles

Boron Extrication An in-depth look into vehicle extrication and rescues involving today's automobiles