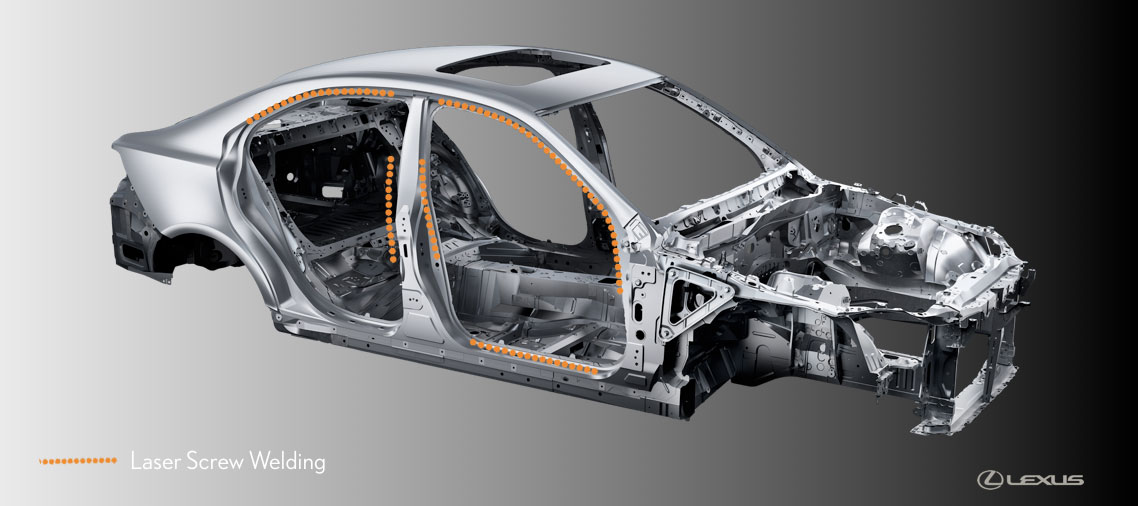

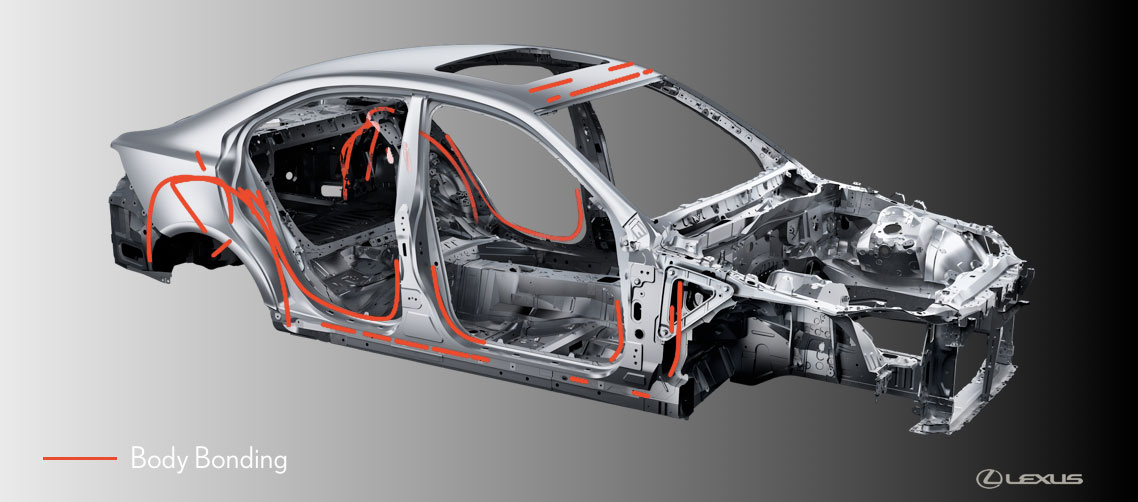

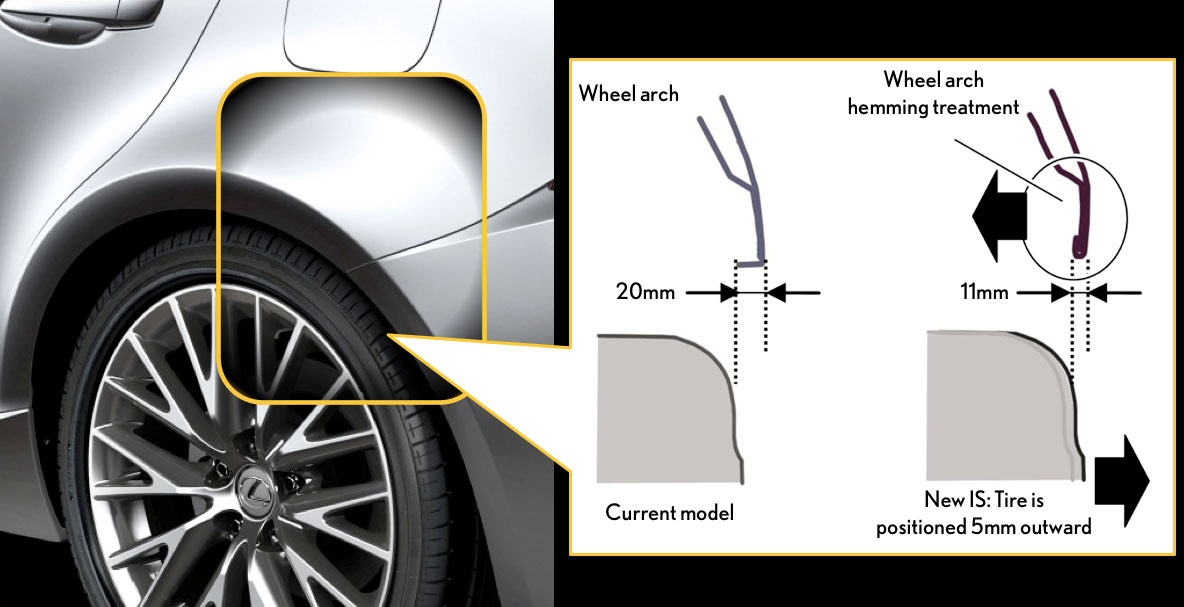

The 2014 Lexus IS has a bunch of different manufacturing methods. Use of body adhesive bonding and laser screw welding are just a few. The body adhesive bonding should be nothing new to readers of this site. But laser screw welding is.

Laser screw welding is a technique that Lexus has developed. It uses a laser to weld steel, but it does so with so little heat that there is no heat-induced distortion of the sheetmetal, as if it were fastened with a sheetmetal screw. Lexus uses laser screw welding to weld the steel all the way around the front door openings and about half of the rear door openings.

Adhesives were used to join body panels over a larger area to make significant improvements to body rigidity. The 2014 Lexus IS uses 25 meters (82 feet) of bonding throughout the body.

- Highly rigid body structure with front and rear crumple zones

- Reinforcements in pillars and door sills

- Side-impact door beams

- Collapsible steering column

- Impact-dissipating upper interior trim

Boron Extrication An in-depth look into vehicle extrication and rescues involving today's automobiles

Boron Extrication An in-depth look into vehicle extrication and rescues involving today's automobiles