What Grade of Chain for Rescue Use?

Answering the question of which grade of chain to use for rescue applications is not so cut and dry. Chains come in various strengths depending on intended usage. Grade 70 chains for example are typically used in towing applications. Grade 80 or better are the only chains rated for overhead lifting. Some say that since Grade 70 chains are used by tow operators to pull and load vehicles onto a flatbed tow truck than rescuers can use them. Others say that you need a chain that is rated for overhead lifting. Firehouse Expo HOT instructor Billy Leach, recommends that only Grade 80 or better should be used for extrication. My department has Grade 70 chains on the heavy rescue. What does your department use? A more important question is what chain should you use?

“Working load limit” “Proof test” and “Minimum break load”

- Weight Load Limit (WLL) is the maximum working load designed by the manufacturer.

- Proof Test is where a load is applied to the newly produced chain as a quality control measure. The proof test is not a performance measure, it is only intended to draw the manufacturer’s attention to any flaws in the chain. The common load applied is twice the WLL, or half the expected break load.

- Minimum Break Load (MBL) is the minimum force which chain or components must withstand before failure.

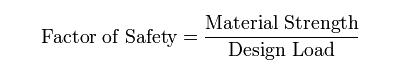

- Safety Factor (SF) is the structural capacity of a chain beyond the expected loads or actual loads. The safety factor is a ratio of maximum strength to intended load for the actual item that was designed. The design load being the maximum load the part should ever see in service.Commonly shown in a ratio like 4:1.

The Meaning of Chain Grade Numbers

The chain grade numbers which manufacturers use are actually one tenth of the actual grades. Therefore, our grade 80 is 800, grade 70 is 700, and so on.

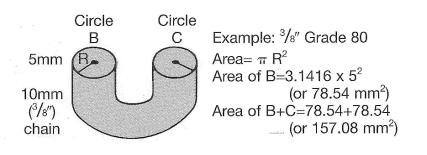

The grade refers to the tensile strength of the chain. This is expressed in newtons per square millimeter (a newton is approximately 0.224805 lbs). The tensile strength is calculated by multiplying the grade times the area of the two cross sections of a link.

(Area) 157.08 mm2 x 800 n (Grade)=125,664 newtons ultimate breaking strength

125,664 newtons x .224805=28,250 lbs ultimate breaking strength

125,664 newtons÷1000=125.66 kn (Kilonewtons)

Is there a strength difference between Grade 70 and 80? Compare a 3/8” Grade 70 that has a working load of 6,600 Lbs with a 4:1 safety factor with a 3/8” Grade 80 that has a working load of 7,100 Lbs with a 4:1 safety factor. The higher grade 80 chain only gives you a 7% gain in strength going from Grade 70 to 80.

So which chain should you use? I referenced a post from Firehouse.com University of Extrication forum named Overhead Lifting and Chain Grade posted by Tim O’Connell. Tim just happens to be the Owner/President of Rescue 42.

Grade 70 chain is made from heat treated Carbon steel which produces a more closed surface porosity as well as removing the high susceptibility to Hydrogen embrittlement. Grade 70 chains are galvanized, Zinc Chromated or treated with some other corrosion resisting sacrificial anode material. They survive the salt spray test for many days (instead of hours for 80/100). They are MUCH tougher than the 80/100 chains. They resist battery acid extremely well due to their sacrificial anode coating as well as their resistance to Hydrogen embrittlement.

Grade 70 chain is the correct choice for extrication. Grade 70 chain is called “Transport” chain. It is made of heat treated Carbon steel. It is still incredibly strong, and the lack of the special alloys both produces a more closed surface porosity as well as removing the high susceptibility to Hydrogen embrittlement. Grade 70 chains are galvanized, Zinc Chromated or treated with some other corrosion resisting sacrificial anode material. They survive the salt spray test for many days (instead of hours for 80/100). They are MUCH tougher than the 80/100 chains. They resist battery acid extremely well due to their sacrificial anode coating as well as their resistance to Hydrogen embrittlement.

Make sure you read the complete post that Tim wrote on FireHouse.com. He contacted several engineers at the two largest chain manufacturers in the US and got their professional opinions.

Hooks and Clusters

Billy Leach has provided a bunch of information on chains and hooks from his HOT classes at Firehouse Expo last week. Make sure you print out, read, and share all of his Hands-On Training Heavy Rescue For Heavy Vehicles pdf handouts below:

- BRR1 Course Handout-5 Step Discipline

- BRR1 Course Handout-Chains

- BRR1 Course Handout-Hooks and Shackles

- BRR1 Course Handout-Synthetic Slings

- BRR1 Course Handout-Timber Cribbing Use

- BRR1 Course Handout-Wire Rope

- BRR1 Course Handout-Wire Rope Termination

Safety

Check Wear Regularly

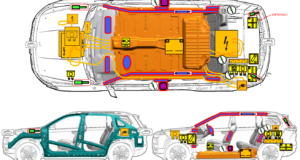

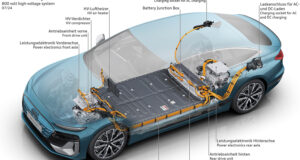

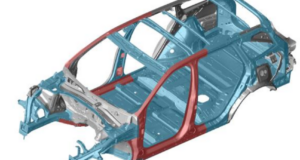

Boron Extrication An in-depth look into vehicle extrication and rescues involving today's automobiles

Boron Extrication An in-depth look into vehicle extrication and rescues involving today's automobiles

Throughout this article the Grade 70 chain is lauded for its inherent characteristics and manufacturing processes, yet in the first BRR1 handout step two stabilization indicates “a minimum of Grade 80 or greater chain “should be used during extrication.” Hardly a ringing endorsement of the information in the article.

I would take the time to reread the first paragraph Pete. I clearly stated that there are two opinions on which grade should be used for extrication. Maybe if you would provide your thoughts and concerns on Grade 70 vs. Grade 80 you would advance the discussion instead of adding nothing. I expect more from a command level guy.

I meant no ill intent with my comment. I apologize for the irritation factor. I learned many things from both the web posting and the handouts. The initial hang up I had was the last line of the first paragraph “what should you use.”

I have a better understanding of the complexity of decision making while using chain and associated devices.

Understood. This article sat as a draft for 6 months until I ran across Billy Leach’s handouts from Firehouse EXPO. I wanted to get people thinking, if anything, to know what grade they have on their trucks.

I have run into both schools of thought on the 70 vs. 80 many times and it’s tough to discount both sides. I would take the word of engineers from chain makers that were solicited from a strut maker like Rescue 42. However, when a guy like Billy Leach puts his name behind grade 80 it makes you want to lean toward the guy with practical knowledge and experience to back it up.

Any chance you could post Tom O’Connell’s post from firehouse.com? I can’t seem to find it on the firehouse website…Chris

http://www.firehouse.com/forums/t120651/

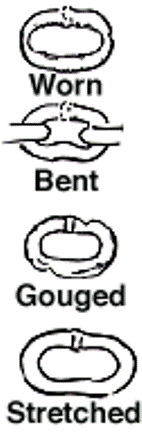

I would always select a grade 80 hook as it provides a higher weight load limit. Remember to select the proper chain hook for your rigging application as well to provide the safety factor. Worn or gouged hooks should never be used.