At the 2021 Bowling Green State University Spring Fire School, we got to spread, cut, and push on a 2021 Ford Bronco Sport. Several notable observations were the A & B-pillars, roof rails, and rocker panels. The pillars were made of different advanced steels and both fractured during cutting operations. The pillars held their pre-cut shape after the cuts. Take a look at the pillars below:

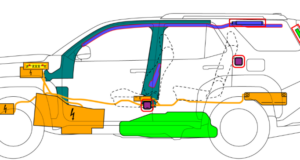

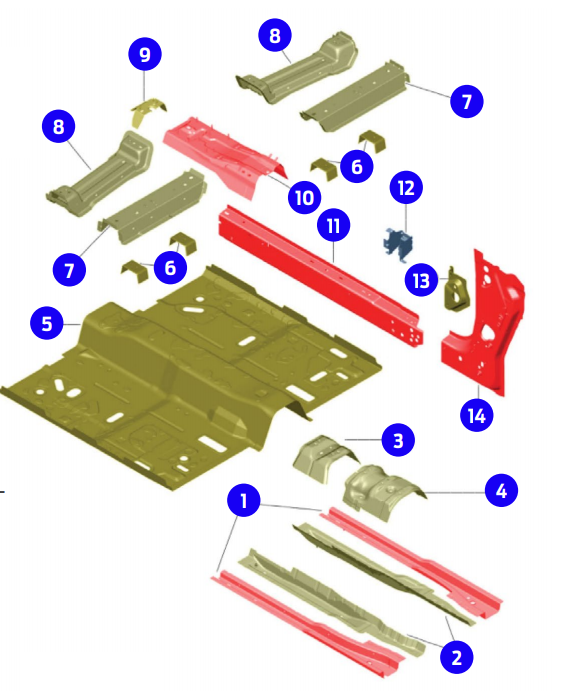

Next, the rocker panels were extremely strong. If you look at the floor pan pictures below, you see that the side panel reinforcement in the rocker panel is made from Boron Steel. We pushed on the rocker panel to tent the roof to gain additional headroom for the front row occupants. The driver-side roof rail reinforcement did crease but the passenger side ripped out. However, a large amount of headroom was gained on both sides. The rocker panel was not cribbed where we pushed with the ram and it barely deflected under the load.

|  |

Lastly, the fender wells were made from advanced steel and required us to completely cut the hinge pillar and deep behind the front tire to lift the dash. Keep in mind, on undamaged vehicles, we are fighting all the reinforcements and engineering design to keep the occupant safe.

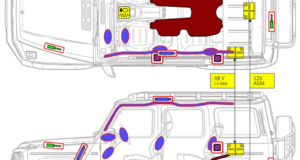

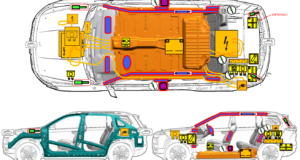

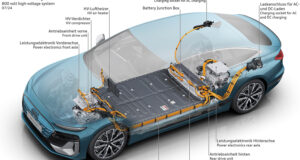

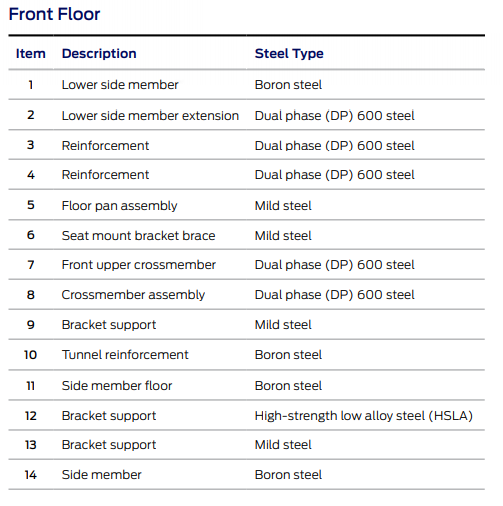

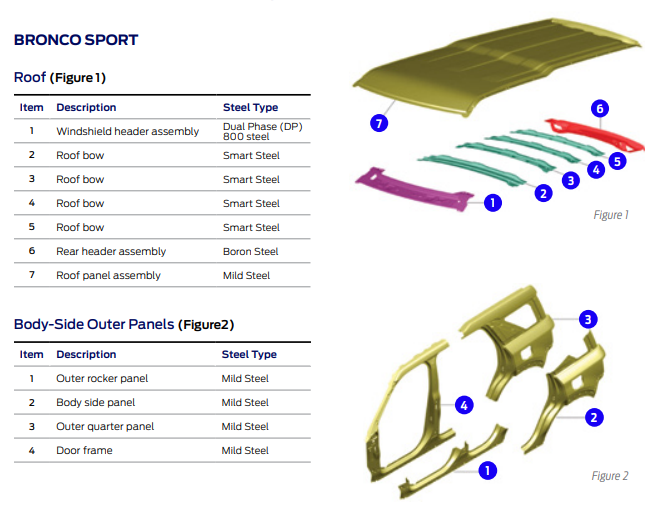

Illustrations of construction details of the Ford Bronco. (“On Target”/Ford Motor Co.)

Boron Extrication An in-depth look into vehicle extrication and rescues involving today's automobiles

Boron Extrication An in-depth look into vehicle extrication and rescues involving today's automobiles